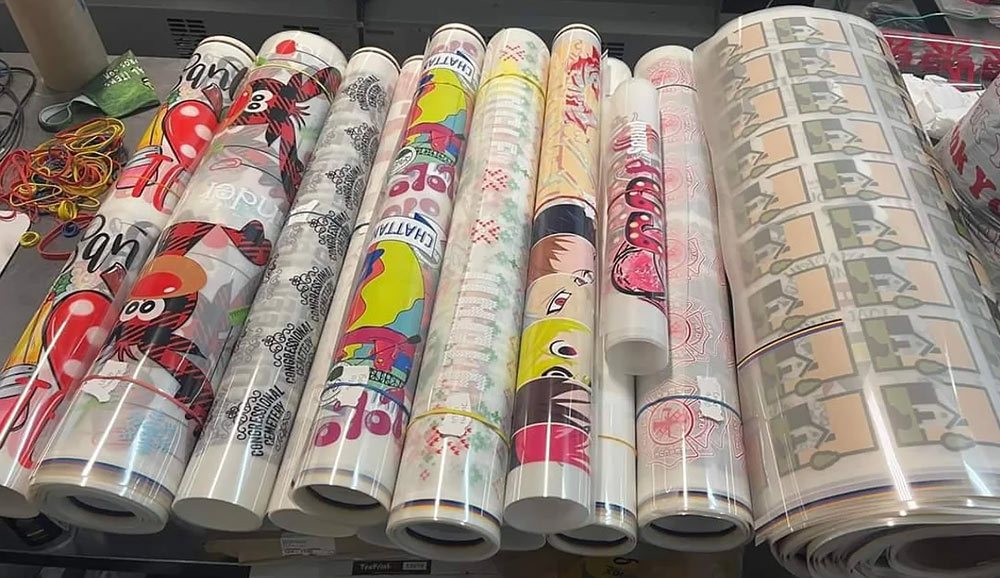

Our By Size products make ordering easier than ever.

- Works on Any Fabric or Color

- Vibrant Colors & Ultra-fine Details

- Quick & Easy Application

- Long Lasting Durability

- 100% Satisfaction Guaranteed

- No Minimums or Setup Fees

Pressing Instructions

To ensure your DTF transfer looks professionally pressed every time, follow these five simple steps.

1. No Need To Pre-Press Or Pre-Iron: Removing moisture is unnecessary. Only do a prepress if you so desire.

2. Position Your Design: Take your time to line up your transfer in the desired location on your item. Normally, there is no need to use heat-resistant tape on flat heat presses to keep your design in place, however it is highly recommended when pressing transfers onto hats or when using an iron to keep the transfer in place. You’ll get a feel for when this is needed.

3. Press: Press your transfer with medium pressure at 310°F / 155°C for 15 seconds. You cannot damage the transfer by pressing with more heat, pressure, or time — within reason. However, too much heat can damage your garment, so test first and use parchment paper or a protective guard sheet to protect your garment from a direct iron.

4. Let It Cool. Then Peel It: After pressing, let your transfer rest until it is cool to the touch (minimum of 15-30 seconds). Once cool, lift the transfer from one corner and gently peel back. If you notice any part of your design is not adhering to your item stop peeling, lay it back down, and trouble shoot as follows — (1.) If some or all of the design does not transfer AND it was cool when peeling, it means there was not enough heat, pressure, or time. Press your transfer again with more pressure and time first (+5-10 seconds). (2.) If that doesn’t work, try 15°F heat increments until you find the sweet spot. You truly cannot damage the transfer by pressing multiple times.

5. Final Press & Wash Instructions: Place the parchment paper ,or a single layer of t-shirt material over the design and press again for 15 seconds to soften the design, increase durability, and remove shine. When washing, flip the shirt inside out, wash on cold and dry using low heat or hang.

Art Upload Recommendations

All file types accepted, vector files are always preferred, raster art should be at least 300 DPI.

Tip: If you’re using Canva or Procreate, we recommend exporting your documents as PDFs

Shop DTF Transfers

-

Every Butt Loves a Rub

Price range: $2.99 through $9.99 -

Deer Santa

Price range: $2.99 through $9.99 -

Fish Around And Find Out

Price range: $2.99 through $9.99